Unveiling the Secrets of Car Control Arms: Enhancing Performance, Comfort, and Safety on the Road

Introduction:

Welcome to the fascinating world of car control arms! In this comprehensive article, we will dive deep into the intricacies of these critical components and explore how they contribute to the overall performance, comfort, and safety of your vehicle. From understanding the functions of control arms to recognizing the signs of wear, we'll equip you with the knowledge you need to make informed decisions about your car's suspension system. So buckle up and get ready to unravel the secrets of car control arms!

I. The Mighty Control Arm:

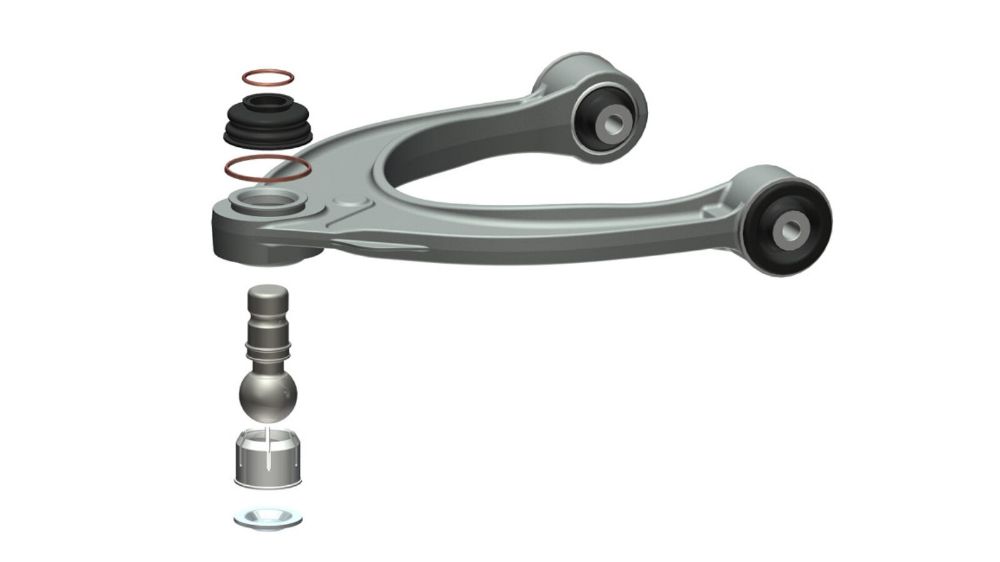

A Foundation for Stability and Control The control arm, also known as an A-arm, is a key component of a vehicle's suspension system. It plays a vital role in connecting the wheel hub to the vehicle's frame or subframe, allowing for controlled movement and absorbing the forces encountered during driving. Let's explore the different parts of a control arm:

-

Ball Joint: A Crucial Linkage The ball joint acts as the pivot point between the control arm and the steering knuckle. It allows for smooth and controlled movement of the wheel, enabling steering and absorbing shocks.

-

Control Arm Bushing: Cushioning the Ride Control arm bushings are rubber or polyurethane components that provide a cushioning effect and reduce vibrations. They help maintain proper alignment and absorb road irregularities for a smoother ride.

-

Control Arm Mounting Bolts: Holding It All Together The control arm mounting bolts secure the control arm to the frame or subframe of the vehicle. They ensure stability and proper positioning of the control arm assembly.

II. Signs of a Failing Control Arm:

Navigating the Warning Signs Like any other component, control arms can experience wear and tear over time. It's important to recognize the signs of a failing control arm to address issues promptly and ensure your safety on the road. Look out for the following indications:

-

Impact on Steering and Handling: A bad control arm can affect steering responsiveness, causing the vehicle to feel loose or unstable. You may also experience difficulty maintaining control during turns or notice unusual noises while maneuvering.

-

Vibrations and Unusual Noises: Worn-out control arm bushings or ball joints can lead to vibrations felt through the steering wheel or the vehicle's chassis. Additionally, you might hear clunking or squeaking noises, especially when going over bumps or during cornering.

-

Uneven Tire Wear: Faulty control arms can disrupt proper wheel alignment, resulting in uneven tire wear patterns. Keep an eye out for excessive or irregular tire wear, such as bald spots or feathering.

-

Deterioration of Ride Quality: If you notice a significant decline in ride comfort, such as a rougher or bumpier ride, it could be a sign of worn-out control arms. They may no longer effectively absorb shocks and vibrations from the road.

-

Excessive Suspension Movement: A failing control arm can cause excessive suspension movement, leading to poor handling, increased body roll, and diminished stability.

III. Addressing Control Arm Issues:

Time for Action When facing control arm problems, it's crucial to take appropriate measures to ensure your safety and maintain the performance of your vehicle. Here are some common questions and answers to guide you:

Can you drive with bad control arms?

While it's not recommended to drive with bad control arms, it's important to assess the severity of the issue. If the control arm is severely damaged or detached, it's unsafe to drive. However, in some cases, you may be able to drive short distances at reduced speeds to reach a repair facility.

Do control arms affect performance?

Yes, control arms significantly impact the performance of your vehicle. They contribute to stability, control, and overall handling. Worn-out control arms can negatively affect steering response, cornering ability, and suspension performance.

When should I replace control arms?

Control arms should be replaced when they exhibit signs of wear, such as damaged ball joints, worn-out bushings, or structural damage. Additionally, if you experience significant handling issues or notice severe suspension movement, it's advisable to have the control arms inspected and replaced if necessary.

How long do control arms last?

The lifespan of control arms can vary depending on factors such as driving conditions, vehicle make and model, and maintenance. On average, control arms may last between 80,000 to 150,000 miles.

Can control arms cause wobble?

Yes, a failing control arm can contribute to a wobbling sensation in the vehicle, especially at higher speeds. This wobble can be a result of compromised stability and control due to worn-out components.

What do bad control arms feel like?

Bad control arms can result in various sensations while driving. You may experience vibrations through the steering wheel or the vehicle's chassis. The steering may feel loose or less responsive, and you might notice a decrease in overall stability and control.

Do control arms improve ride quality?

Yes, control arms play a significant role in enhancing ride quality. They help absorb shocks and vibrations from the road, ensuring a smoother and more comfortable driving experience.

Do control arms help with alignment?

Yes, control arms contribute to maintaining proper wheel alignment. Worn-out control arms can lead to misalignment, affecting tire wear patterns and overall handling.

Do control arms give you camber?

Control arms are not directly responsible for adjusting camber. However, they can influence camber angles indirectly by affecting wheel alignment. Properly functioning control arms help maintain correct camber angles.

Can a control arm be repaired?

In most cases, control arms are not repaired but replaced as a complete assembly. This ensures the integrity and reliability of the suspension system. If there is minor damage or wear to certain components, such as bushings or ball joints, they can be replaced individually.

How do you test control arms?

Control arms can be inspected visually for signs of wear, such as damaged bushings, ball joint play, or structural damage. Additionally, a mechanic may perform a physical inspection and conduct a suspension system evaluation, which may involve checking for excessive movement or performing a bounce test.

Should I replace the control arm or just bushings?

It depends on the extent of wear or damage. If the control arm itself is severely worn or damaged, it's advisable to replace the entire assembly. However, if the control arm is structurally sound and only the bushings are worn, you may opt to replace the bushings alone.

How serious are control arm bushings?

Control arm bushings play a critical role in providing cushioning, stability, and proper alignment. Worn-out or damaged control arm bushings can lead to increased vibrations, compromised handling, and accelerated tire wear. Prompt replacement is necessary to maintain optimal suspension performance and safety.

Can I drive with bad control arm bushings?

It's not recommended to drive with bad control arm bushings for an extended period. Worn-out bushings can negatively impact vehicle stability, handling, and alignment. It's best to have them replaced to ensure the proper functioning of the suspension system.

What do damaged ball joints sound like?

Damaged ball joints can produce clunking or creaking sounds, especially when going over bumps or during steering maneuvers. The noises may vary depending on the severity of the ball joint wear or damage.

What happens if a ball joint breaks while driving?

If a ball joint breaks while driving, it can cause a significant loss of control over the affected wheel. The vehicle may become difficult to steer, leading to a sudden and dangerous change in direction. It's crucial to bring the vehicle to a safe stop and have it towed for repairs.

Is a trailing arm a control arm?

No, a trailing arm is a separate component of the suspension system. While both control arms and trailing arms contribute to the overall stability and control of the vehicle, they serve different functions and have distinct designs. Trailing arms primarily assist in locating and controlling the movement of the rear suspension.

IV. Key Takeaways:

- Car control arms are crucial components of the suspension system, connecting the wheel hub to the vehicle's frame.

- The ball joint, control arm bushing, and control arm mounting bolts are essential parts of the control arm assembly.

- Signs of a failing control arm include impact on steering and handling, vibrations and unusual noises, uneven tire wear, deterioration of ride quality, and excessive suspension movement.

- Promptly addressing control arm issues is vital for safety and maintaining optimal vehicle performance.

- If you experience control arm problems, consult with a professional mechanic to assess the condition and determine the necessary repairs or replacements.

Conclusion:

Car control arms play a pivotal role in ensuring stability, control, and comfort during your driving experience. By understanding their functions, recognizing signs of wear, and taking appropriate action, you can enhance the performance, safety, and longevity of your vehicle. Regular inspections and maintenance are key to identifying and addressing control arm issues before they escalate. Remember, a well-maintained suspension system, with healthy control arms, will contribute to a smoother, more enjoyable ride on the road.